Section 4 of 15

Section 3: Transporting Cargo Safely

This section tells you about hauling cargo safely. You must understand basic cargo safety rules to get a CDL.

If you load cargo wrong or do not secure it properly, it can be a danger to others and yourself. Loose cargo that falls off a vehicle can cause traffic problems and others could be hurt or killed. Loose cargo could hurt or kill you during a quick stop or accident. Your vehicle could be damaged by an overload. Steering could be affected by how a vehicle is loaded, making it more difficult to control the vehicle. Whether or not you load and secure the cargo yourself, you are responsible for:

- Inspecting your cargo.

- Recognizing overloads and poorly balanced weight.

- Knowing your cargo is properly secured and does not obscure your view ahead or to the sides.

- Knowing your cargo does not restrict your access to emergency equipment.

If you intend to carry HazMat that requires placards on your vehicle, you will also need to have an “H” endorsement. Section 9 of this handbook has the information you need to pass the HazMat test.

3.1 – Inspecting Cargo

As part of your vehicle inspection, make sure the truck is not overloaded and the cargo is balanced and secured properly.

After Starting. Inspect the cargo and its securing devices again within the first 50 miles after beginning a trip. Make any adjustments needed.

Re-Check. Re-check the cargo and securing devices as often as necessary during a trip to keep the load secure. You need to inspect again:

- After you have driven for 3 hours or 150 miles.

- After every break you take during your trip.

Federal, state, and local regulations for CMV weight, securing cargo, covering loads, and where you can drive large vehicles vary from place to place. Know the rules where you will be driving.

3.2 – Cargo Weight and Balance

You are responsible for not being overloaded. The following are some definitions of weight you should know.

3.2.1 – Definitions You Should Know

Gross Vehicle Weight (GVW). The total weight of a single vehicle including its load.

Gross Combination Weight (GCW). The total weight of a combination of vehicles including the load.

Gross Vehicle Weight Rating (GVWR). The value specified by the manufacturer as the loaded weight of a single vehicle.

Gross Combination Weight Rating (GCWR). The value specified by the manufacturer as the loaded weight of a combination (articulated) vehicle. In the absence of a value specified by the manufacturer, GCWR will be determined by adding the GVWR of the power unit, the total weight of the towed unit, and any load thereon.

Axle Weight. The weight transmitted to the ground by 1 axle or one set of axles.

Tire Load. The maximum safe weight a tire can carry at a specified pressure. This rating is stated on the side of each tire.

Suspension Systems. Suspension systems have a manufacturer’s weight capacity rating.

Coupling Device Capacity. Coupling devices are rated for the maximum weight they can pull and/or carry.

3.2.2 – Legal Weight Limits

You must keep weights within legal limits. States have maximums for GVWRs, GCWRs, and axle weights. Often, maximum axle weights are set by a bridge formula. A bridge formula permits less maximum axle weight for axles that are closer together. This is to prevent overloading bridges and roadways.

Overloading can have bad effects on steering, braking, and speed control. Overloaded trucks have to go very slowly on upgrades. Worse, they may gain too much speed on downgrades. Stopping distance increases. Brakes can fail when forced to work too hard.

During bad weather or in mountains, it may not be safe to operate at legal maximum weights. Take this into account before driving.

3.2.3 – Do Not Be Top-Heavy

The height of the vehicle’s center of gravity is very important for safe handling. A high center of gravity (cargo piled up high or heavy cargo on top) means you are more likely to tip over. It is most dangerous in curves, or if you have to swerve to avoid a hazard. It is very important to distribute the cargo so it is as low as possible. Put the heaviest parts of the cargo under the lightest parts.

3.2.4 – Balance the Weight

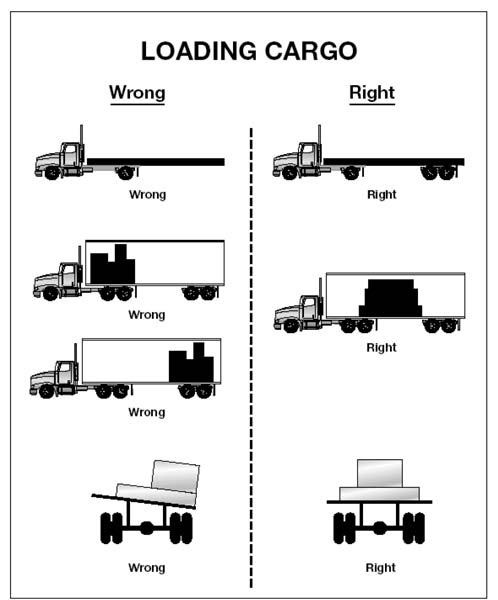

Poor weight balance can make vehicle handling unsafe. Too much weight on the steering axle can cause hard steering. It can damage the steering axle and tires. Under-loaded front axles (caused by shifting weight too far to the rear) can make the steering axle weight too light to steer safely. Too little weight on the driving axles can cause poor traction. The drive wheels may spin easily. During bad weather, the truck may not be able to keep going. Weight loaded with a high center of gravity causes a greater chance of rollover. On flatbed vehicles, there is also a greater chance that the load will shift to the side or fall off. See Figure 3.1.

3.3 – Securing Cargo

3.3.1 – Blocking and Bracing

Blocking is used in the front, back, and/or sides of a piece of cargo to keep it from sliding. Blocking is shaped to fit snugly against cargo. It is secured to the cargo deck to prevent cargo movement. Bracing is also used to prevent movement of cargo. Bracing goes from the upper part of the cargo to the floor and/or walls of the cargo compartment.

Figure 3.1

3.3.2 – Cargo Tie-down

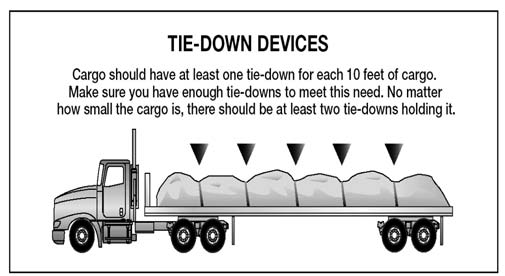

On flatbed trailers or trailers without sides, cargo must be secured to keep it from shifting or falling off. In closed vans, tiedowns can also be important to prevent cargo shifting that may affect the handling of the vehicle. Tiedowns must be of the proper type and proper strength. Federal regulations require the aggregate working load limit of any securement system used to secure an article or group of articles against movement must be at least 1/2 times the weight of the article or group of articles. Proper tie-down equipment must be used, including ropes, straps, chains, and tensioning devices (such as, winches, ratchets, and clinching components). Tiedowns must be attached to the vehicle correctly (with hooks, bolts, rails, rings). See Figure 3.2.

Figure 3.2

Cargo should have at least one tie-down for each 10 feet of cargo. Make sure you have enough tie-downs to meet this need. No matter how small the cargo, it should have at least 2 tie-downs.

There are special requirements for securing various heavy pieces of metal. Find out what they are if you are to carry such loads.

Rules governing the loading and securement of logs, dressed lumber, metal coils, paper rolls, concrete pipe, intermodal containers, automobiles, heavy vehicles, flattened or crushed vehicles, roll-on/roll-off containers, and large boulders are contained in CFR, Title 49 §393.

3.3.3 – Header Boards

Front-end header boards (“headache racks”) protect you from your cargo in case of an accident or emergency stop. Make sure the front-end structure is in good condition. The front-end structure should block the forward movement of any cargo you carry.

3.3.4 – Covering Cargo

There are 2 basic reasons for covering cargo:

- To protect people from spilled cargo.

- To protect the cargo from weather.

Spill protection is a safety requirement in many states. Be familiar with the laws in the states you drive in.

You should look at your cargo covers in the mirrors from time to time while driving. A flapping cover can tear loose, uncover the cargo, and possibly blocking your view or someone else’s.

3.3.5 – Sealed and Containerized Loads

Containerized loads generally are used when freight is carried part way by rail or ship. Delivery by truck occurs at the beginning and/or end of the journey. Some containers have their own tiedown devices or locks that attach directly to a special frame. Others have to be loaded onto flatbed trailers. They must be properly secured just like any other cargo.

You cannot inspect sealed loads, but you should check that you do not exceed gross weight and axle weight limits.

3.3.6 – Spilling Loads and Damage to the Highway

It is against the law to operate on the highway a vehicle which is improperly covered, constructed, or loaded so that any part of its contents or load spills, drops, leaks, blows, sifts, or in any other way escapes from the vehicle. EXCEPTION: clear water or feathers from live birds (CVC §§23114 and 23115).

Any vehicle transporting garbage, trash, rubbish, ashes, etc., must have the load covered to prevent any part of the load from spilling on to the highway. Aggregate material must be carried in the cargo area of the vehicle and be 6 inches below the upper edge. The cargo area must not have any holes, cracks, or openings which could allow the material to escape. The vehicle used to transport aggregate material must be equipped with seals on any openings used to empty the load, splash flaps behind every tire or set of tires, and fenders. Other requirements are listed in CVC §23114. This does not apply to vehicles carrying wet, waste fruit, or vegetable matter, or waste from food processing plants.

Any person who willfully or negligently damages any street or highway is liable for the cost of repairing the road or any sign, signal, guard rail, or other facility that is damaged. The liability may include the cost of removing debris from the roadway.

3.4 – Cargo Needing Special Attention

3.4.1 – Dry Bulk

Dry bulk tanks require special care because they have a high center of gravity, and the load can shift. Be extremely cautious (slow and careful) going around curves and making sharp turns.

3.4.2 – Hanging Meat

Hanging meat (suspended beef, pork, lamb) in a refrigerated truck can be a very unstable load with a high center of gravity. Particular caution is needed on sharp curves such as off ramps and on ramps. Go slowly.

3.4.3 – Livestock

Livestock can move around in a trailer, causing unsafe handling. With less than a full load, use false bulkheads to keep livestock bunched together. Even when bunched, special care is necessary because livestock can lean on curves. This shifts the center of gravity and makes rollover more likely.

3.4.4 – Oversized Loads

Over-length, over-width, and/or overweight loads require special (CalTrans in California) transit permits. Driving is usually limited to certain times. Special equipment may be necessary such as “wide load” signs, flashing lights, flags, etc. Such loads may require a police escort or pilot vehicles bearing warning signs and/or flashing lights. These special loads require special driving care.

3.4.5 – Special Markings Needed

Any vehicle and load over 80 inches in width must, in addition to required vehicle lighting, show an amber combination clearance and side-marker lamp on the side of the load projection at the front and show a red combination clearance and side-marker lamp on the side of the projection at the rear.

Alternatively, if the over width of the projection does not extend more than 3 feet from front to rear, and the projection is near the front of the vehicle, at least one amber combination clearance lamp must be visible from the front, side, and rear at the extreme width. If the projection is near the rear, at least one red combination side clearance lamp must be displayed (CVC §25100).

3.4.6 – Projecting Loads

Lights (or Flags) on Projecting Loads. When the load on any vehicle extends 4 feet (48 inches) or more beyond the rear of the body, a solid red or fluorescent orange flag at least 12 inches square must be placed at the extreme end of the load. If the vehicle is operated during darkness, there must be 2 lit red lights at the end of the load, visible at a distance of 500 feet to the side and rear of the vehicle (CVC §24604).

A load extending 1 foot or more to the left on any vehicle must have an amber light on the extreme left side of the load. It must be visible at least 300 feet to the front and rear during darkness. If the load extends more than 120 inches, there must be an amber lamp at the front and a red lamp at the rear, each visible at least 300 feet.

If the vehicle is wider than 102 inches, a red or fluorescent flag not less than 12 inches square must be displayed at the left front and left rear during daylight (CVC §25104).

3.4.7 – Piggyback Trailers

When any trailer is loaded upon another vehicle (piggyback) to be moved on any highway, the trailer must be securely bound to the vehicle to prevent the trailer from shifting, toppling over, or becoming unstable.

SECTION 3

Test Your Knowledge

- What four things related to cargo are drivers responsible for?

- How often must you stop while on the road to check your cargo?

- How is gross combination weight rating different from gross combination weight?

- Name 2 situations where legal maximum weights may not be safe.

- What can happen if you do not have enough weight on the front axle?

- What is the minimum number of tiedowns for any flatbed load?

- What is the minimum number of tiedowns for a 20-foot load?

- Name the 2 basic reasons for covering cargo on an open bed.

- What must you check before transporting a sealed load?

These questions may be on your test. If you cannot answer them all, reread Section 3.